As an indispensable active and passive component of electronic products, it has been widely used in various electronic products. In recent years, as most electronic products have became thinner, smaller, and more reliable designs, and used them in automotive electronic products, medical products, high-end servers, military regulations or wearable products, the difficulties of their design parts are increasing. The reliability of the product itself is definitely one of the key points that make the company’s products stand out. To help customers solve design and quality problems, SGS Reliability Laboratory provides comprehensive testing services and consulting. Through professional testing, we can help you design high-reliability and high-quality parts, and promote the parts to enter the competitive market. Stand out, and enhance the company’s value.

PCBA

- IPC TM-650 Series testing

- Cross-section Test/ Bending Test/ Peeling Test/ Thermal Stress Test (T260/ T288)/ Glass Transition Temperature (Tg)/ Z-axis CTE/ Vibration Test/ Thermal Shock Test/ Ion-Migration Test/ Composite temperature/humidity Test/ Autoclave Test/ Withstand Voltage Test/ Insulation Resistance Test

- IPC 6012 (PCB) / IPC 6013 (FPC) / IPC 6016 (HDI) / IPC4101 of Rigid Printed Board and Flexible Printed Board Qualification Test

- IPC A 610D Acceptability of Electronic Assemblies

- JESD 201 Tin Whisker Susceptibility of Tin and Tin Alloy Surface Finishes

- J-STD-020 Moisture/Reflow Sensitivity Classification for Nonhermetic Solid State Surface Mount Devices

- J-STD-002 Solderability Tests for Component Leads, Terminations

- IPC 9701 Qualification Requirements for Surface Mount Solder Attachments

- IPC 9702 Monotonic Bend Characterization of Board-Level Interconnects

- IPC 9704 Printed Circuit Assembly Strain Gage Test Guideline

- Dye & Pry Test

- X-Ray Inspection (Solder Joints on PCBAs)

- C-mode Scanning Acoustic Microscope Analysis

- SEM/ EDS Elemental Analysis

- Thickness measurement for final finish or coating

- SIR/ Ion Migration Test & Conductive Anodic Filament (CAF) Resistance Test

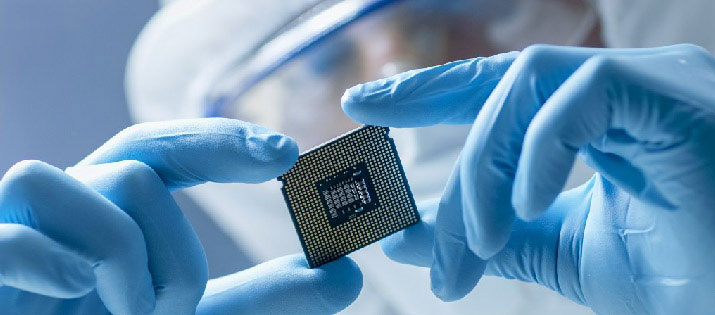

Active / Passive Component

- AEC Q100 (integrated circuits) / AEC Q101 (DISCRETE SEMICONDUCTORS) / AEC Q103 (MEMS DEVICES) / AEC Q104 (MCM DEVICES) /AEC Q200 (PASSIVE COMPONENTS)

- JEDEC 22 Series Testing for SOLID STATE COMPONENTS

- MIL-STD-202 Military Standard for ELECTRONIC AND ELECTRICAL COMPONENT PARTS

- EIAJ Japan Electronics and Information Technology Industries Association

- IEC 60384 Series Test for Capacitors

- Evaluation of customer factory regulation tests