-

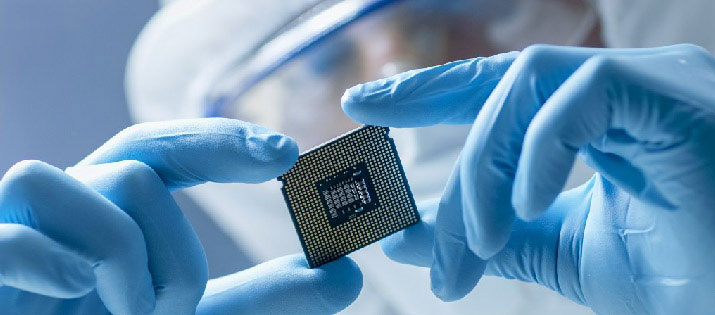

Quality Assurance ProgramManufacturing is a complex process that involves various stages of incoming supply control, production, verification, packaging, and shipment. Every segment of the manufacturing process is governed by strict operational procedures and quality requirements. Audit and inspection are at the forefront of product quality to avoid defects being carried out to the end of the manufacturing process. But one inspection is not enough, brands will deploy QA engineering teams or outsourcing contractors to engage in random audits and FATP to maintain high yield rates.Inquiry

Quality Assurance ProgramManufacturing is a complex process that involves various stages of incoming supply control, production, verification, packaging, and shipment. Every segment of the manufacturing process is governed by strict operational procedures and quality requirements. Audit and inspection are at the forefront of product quality to avoid defects being carried out to the end of the manufacturing process. But one inspection is not enough, brands will deploy QA engineering teams or outsourcing contractors to engage in random audits and FATP to maintain high yield rates.Inquiry