Quality assurance management is one of the fundamental elements of enterprises. For example, 7 quality management (QM) principles in ISO 9000:2015, 8D report system by Ford motor, A3 report system by Toyota motor, and Quality 4.0 of Industry 4.0. No matter which quality assurance method corporations choose, if yield rate testing is not executed thoroughly at the production line, then the QA system will certainly fail. In a mass production process, it needs faster, more, and more effective data management. Only transient manually sampling tests are not sufficient to the high quality management demand presently.

Unable to effectively execute QA system, various potential risks have emerged

1. Insufficient testing capability

When negotiating product contracts, the competitor excels in shipment inspection with a higher testing capacity, primarily relying on data for quality control. However, when our own production line’s inspection rate lags behind a specific proportion of the shipment quantity, it often makes it easier for the competitor to seize the advantage.

2. Annoying and numerous customer complaints

When a customer feedback deviates from the QC results, urgently restarting the verification project and discussing review reports can address immediate issues. However, can this truly eliminate customer and consumer concerns about product development and production line capabilities? Not necessarily! With the increasing influx of defective products into the market and a rise in customer complaints, the brand image is inevitably severely impacted.

3. Unstable testing data

In addition to the rapid measurement, if the outputted test results lack precision and stability, it can easily lead to confusion among engineers in the production stage regarding issues such as equipment, materials, and processing. Simultaneously, this confusion can lead to decision-makers at a loss.

Allion delivers the most reliable solution

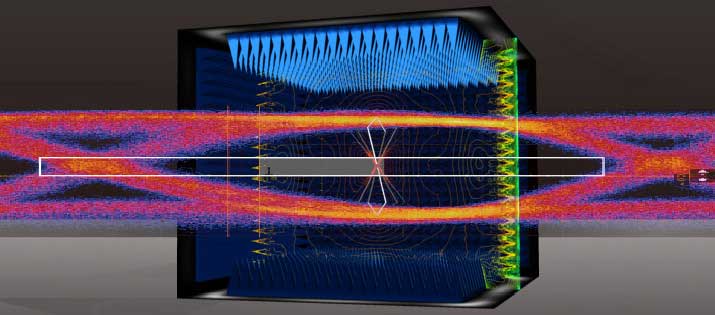

In the production process of a cable, the most annoying issue must be high-frequency testing procedures. It takes too much time and depends on the professional experts with high-frequency knowledge. Allion has been deeply involved in certification testing and consulting services for many years, and well aware of the challenges of high-frequency measurements and the difficulties associated with large-scale testing. We developed Allion Cable-Connector Multiport System (ACMS) to solve this problem, as our unique total solution for customers.

About ACMS:

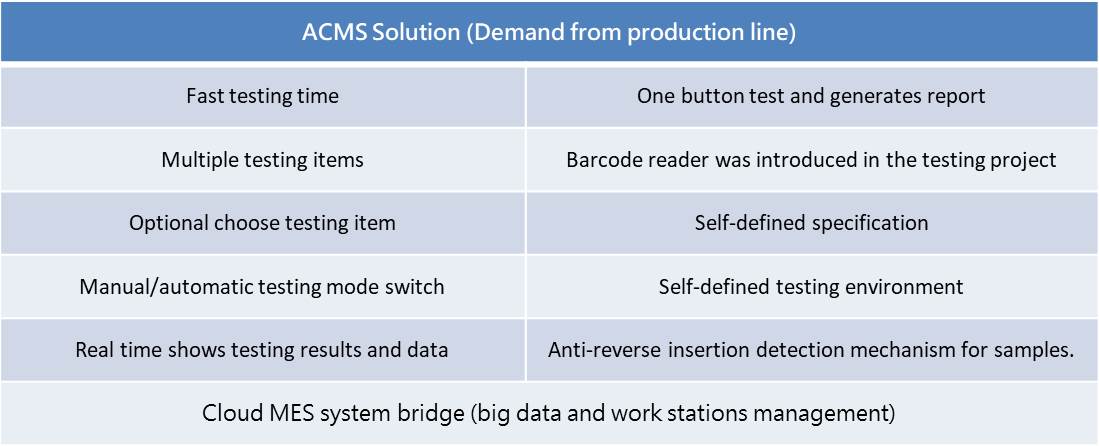

ACMS is an automatic testing system which is capable with the keysight E5071C 20 GHz. It is equipped with 24 measurement ports, allowing for design and utilization based on the number of channels for the test object. We take the USB Type-C interface as an example. It is equipped with 20 automatic measurement ports and 4 manual measurement ports, users can easily switch between automatic measurement and manual verification. Software in this system can be developed and customized depending on customer’s demand. It can fulfill both regular verification and customized testing.

At the preliminary stage, Allion focused on making the testing result precision of ACMS to achieve the standard of verification. The results were approved by Intel and were authorized to be used in the TBT 4 certification testing. Then, Allion received a request from a famous Cable/Connector manufacturer in Japan. After multiple visits and discussions, the R&D and testing teams from Allion gained a thorough understanding of the production line requirements and pain points. They have tailored a dedicated testing system specifically for the Type C 20Gbps for this production line. Allion successfully delivers a fine solution to the high-frequency testing difficulties of that production line.

Allion can provide a faster, easier and better integrated consulting services and solutions.

Based on the close collaboration experience between Allion and the cable industry, we have summarized our three major advantages, assisting clients in achieving comprehensive high-frequency automated measurement capabilities and control systems for production line quality history

Faster:

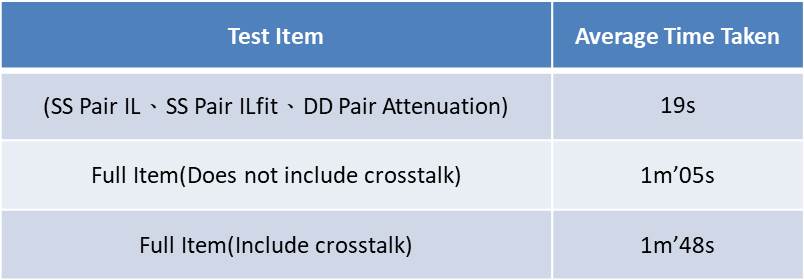

Allion has the most comprehensive professional team in the industry, integrating expertise in software, hardware, testing, and research and development. We provide clients with consulting services at various stages of product development. Leveraging our accumulated technical experience, we swiftly address client challenges. Given the critical nature of every second in the high-frequency and high-volume testing demands of production lines, ACMS’s outstanding performance of testing time can effectively assist clients in achieving 100% detection.

Easier:

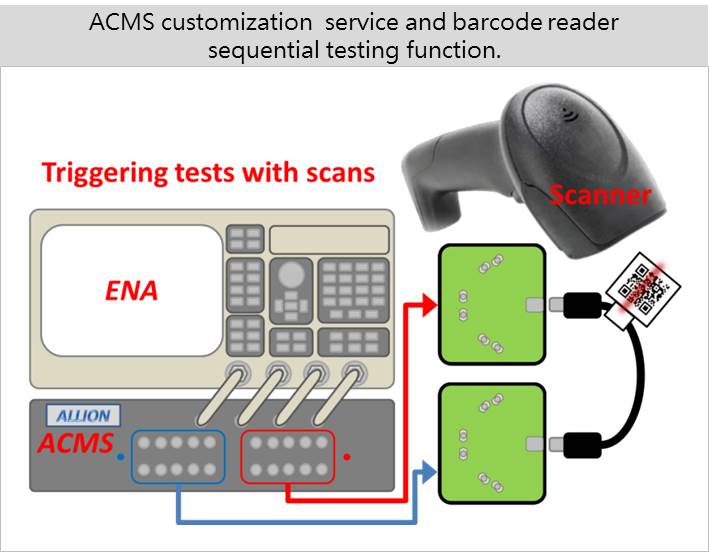

Despite the excellent testing speed, ACMS by Allion is also compatible with barcode reader testing projects. In the numerous testing processes, testers can work more precisely. The customization services for software are designed to closely align with the habits and requirements of both testers and the R&D department.

Better:

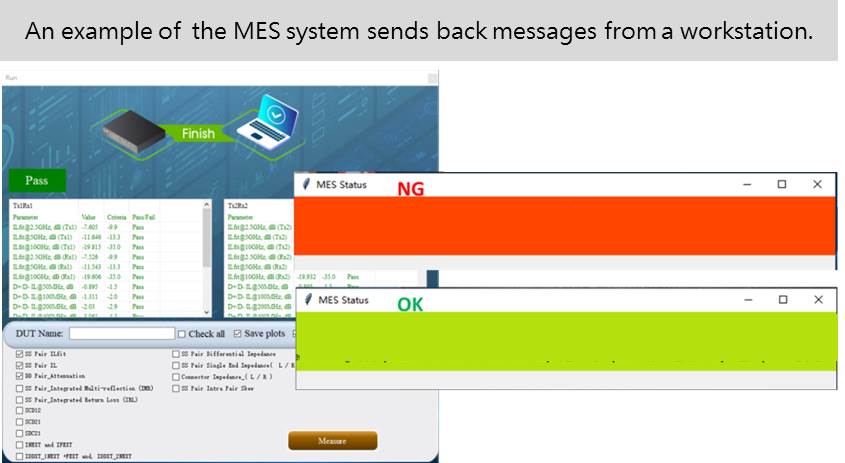

In the customized service, ACMS is able to connect and integrate with the cloud database of the production line. Not only does it provide a clear overview of product data, but it also allows for the inspection of each item to determine if there were occurrences of station skipping or multiple reworks during the production process. Then, this allows for real-time feedback on whether there are any operational issues occurring in the production line.

In addition, Allion offers automated production line quality history management services. Beyond ACMS, we provide various tools to assist production lines in enhancing their control capabilities. By utilizing hardware and software for monitoring and integration, we improve time management, optimize yield rates, and promptly address issues, helping clients maintain optimal competitiveness in the production process.

If you have any further needs for testing, verification, or consulting services related to the cable and connector, please feel free to contact with us.