USB is the most used technology in consumer electronics. Since its introduction, the fast, convenient, and reliable data transmission and charging functions have made it an indispensable part of modern life. USB technology continues to evolve and update. From the original USB 1.0 to the current USB 3.0 and 3.1. There is even a USB4 standard. Each generation of USB technology gives users a faster and more efficient experience. USB connectors are also constantly evolving. The USB Type-A has evolved to Micro-USB and Mini-USB. Now the most commonly used USB Type-C is the mainstream option. Each stage of the USB evolution represents advances in technology and changes in user demands.

USB is often used in electronics, at the same time, USB issues often occur. Recently, the iPhone 15 was launched and changed to a USB Type-C connector, triggering a discussion about overheating during charging. There are many reasons for overheating during charging. From the most basic level, the design and material of the connector are both basic reasons why this happens.

Poor Product Design Leads to Heavy Losses

When the USB connector is poorly designed, it causes the temperature of the cable or the connected device to rise. When this happens, it could lead to unstable data transmission or stop the connected device from charging. Even worse, the connected device could be permanently damaged from overheating and data will be lost. In the worst-case scenario, an electrical fire may be caused, possibly resulting in heavy losses. All of the above scenarios are unacceptable for consumers.

Allion Takes Care of You and Provides the Most Effective Custom Solutions

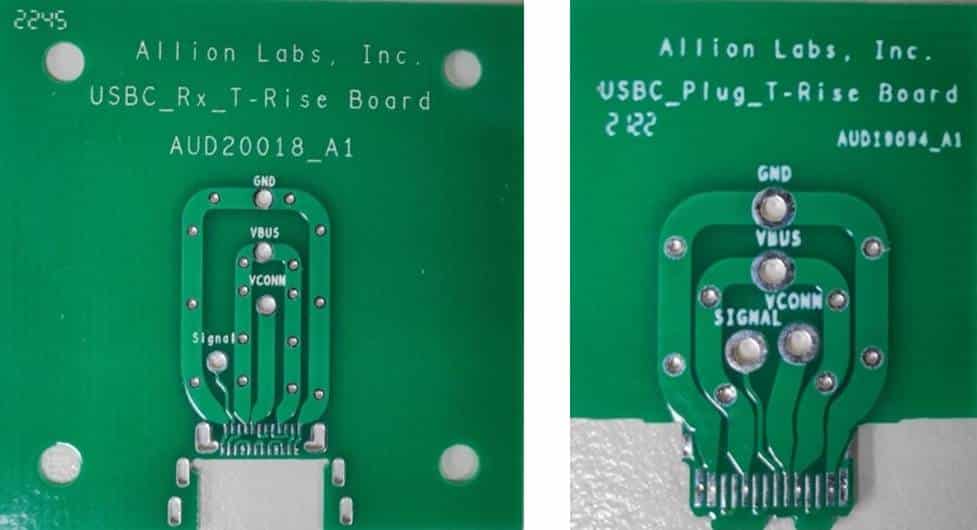

Allion can provide custom designs that are manufactured by official specifications and high-quality T-Rise boards that can measure temperature changes for connectors and cables to alter them by the power supply and electronic load. Official association specifications are used as standards to prevent potential risks from occurring.

Faster, Easier, Better: The Most Trusted USB Product and Cable Testing Consultant

Allion has more than two decades of testing experience with USB connectors and cables, providing comprehensive consulting services for clients which are listed below.

Early Product Design Stage:

- Assist clients with reviewing designs for flaws or potential issues

- Provide clients with simulation tests to determine whether the product meets expected requirements.

Product Verification:

- Assist clients with designing tests, making testing fixtures, and reducing the overall burden on the client by helping with other tasks

- Perform product verification testing to confirm product quality

- Help analyze the cause of the issue when it is discovered

- Provide debugging support as soon as possible when issues are found

- Provide solution suggestions when issues are found

Product Certification:

- Provide consulting services for the certification process such as steps, application documents, requirements, sample preparation, and more.

- Allion is a USB Association-approved testing laboratory that can conduct certification tests, helping clients quickly obtain certificates.

If you have any further needs for testing, verification, or consulting services related to the server ecosystem, please feel free to explore the following services online or contact us through the online form.