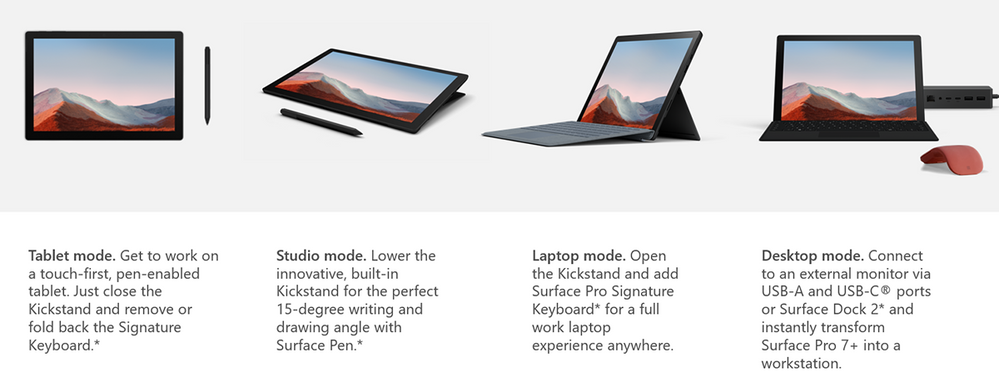

In the era emphasizing portability, the “2-in-1 laptop,” commonly referred to as a convertible or detachable laptop tablet, has become a sought-after 3C product for many consumers. When it comes to 2-in-1 laptops, whether it’s their bidirectional connection design, the unique feature of separating the display panel from the keyboard base, or the versatility of operating in laptop mode, tablet mode, tent mode, and stand mode, among others, allows users to adjust freely in different usage scenarios. The lightweight and flexible convenience has provided an excellent user experience for the majority of consumers. However, it is precisely this unique design that harbors potential risks often overlooked by traditional laptop manufacturers in product design.

The Durability Risks of 2-in1 Laptop

Typically, 2-in-1 laptops use Pogo Pin or magnetic connectors to transmit signals between the display panel and keyboard base. However, if there are design flaws, poor quality materials, or assembly issues during the early stages, it can lead to poor contact between the panel and base, affecting signal communication. This can result in the malfunction of the keyboard base (including the keyboard, hard drive, I/O expansion slots, etc.), ultimately leading to customer complaints. The trouble is that such durability risks often cannot be effectively identified during the development stage but tend to emerge gradually after the product has been on the market for some time.

Case Studies in HALT (Highly Accelerated Life Testing)

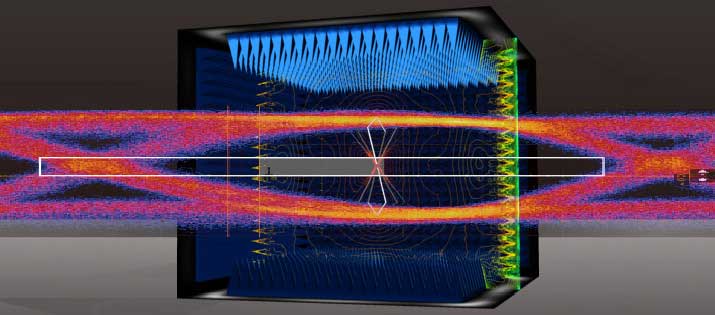

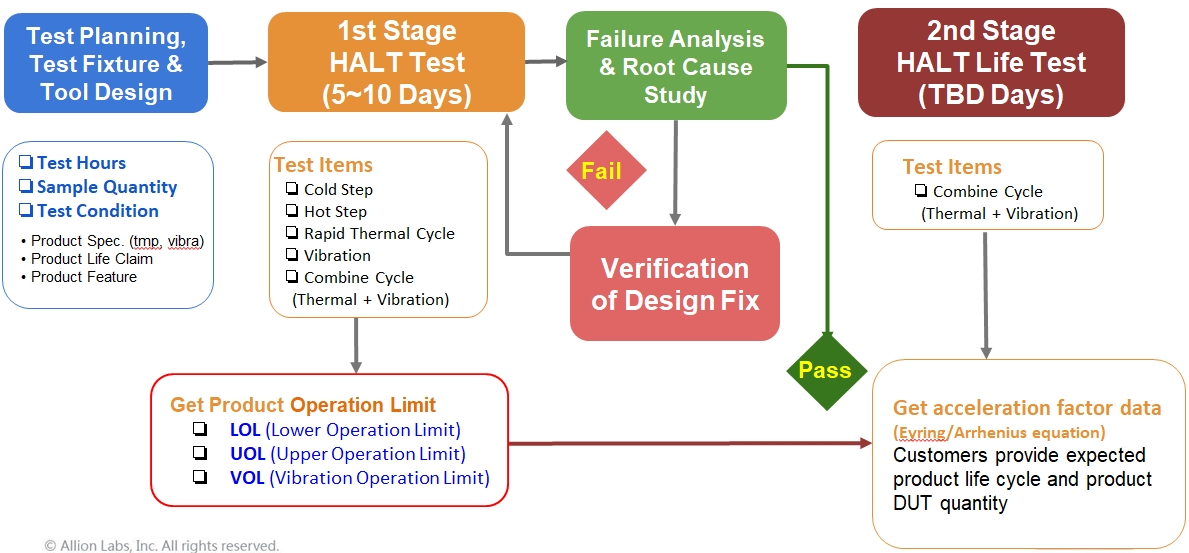

To address durability issues with such products, Allion’s professional consulting team recommends that manufacturers conduct Highly Accelerated Life Testing (HALT) to identify and prevent potential design flaws early. HALT is a method used to rapidly evaluate the strengths and weaknesses of a product’s design during its initial and intermediate stages. By subjecting the product to progressively increasing and stringent environmental stresses, HALT aims to uncover weaknesses and related defects in the product’s design, manufacturing, and usage at different stages.

HALT Test Process

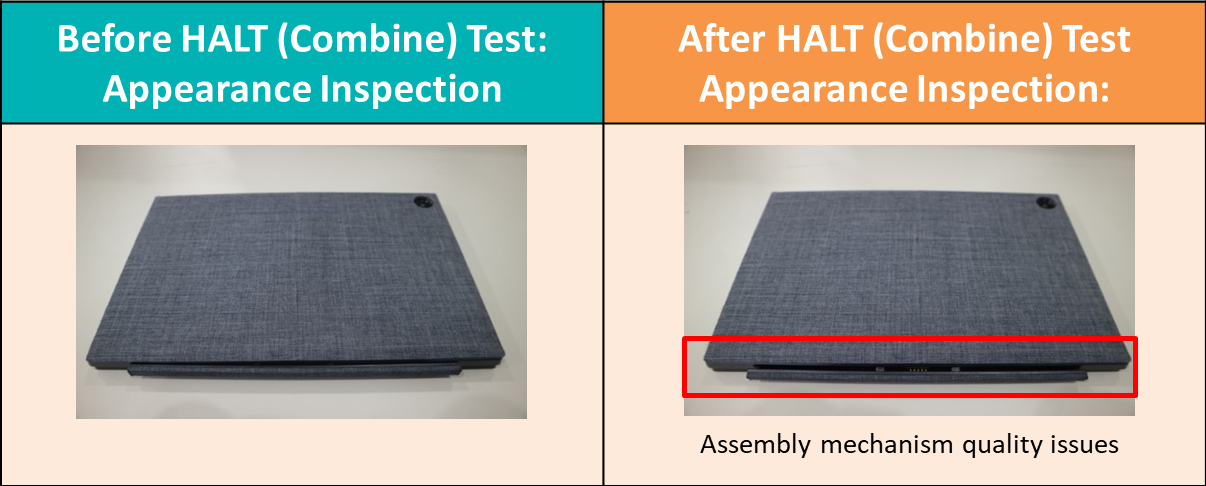

In past collaboration cases, we have assisted manufacturers in conducting highly accelerated life testing for their 2-in-1 laptop. As various stresses were applied incrementally and simultaneously, we discovered issues such as poor fixation of the plastic guides at both ends of the hinge, as well as the inability of the magnetic parts between the panel and keyboard base to adhere properly. Consequently, this led to problems with the keyboard base where typing was not possible and the hard drive could not be recognized. Adjustment of the angle was required to ensure proper adhesion of the magnetic parts before normal use could resume. Additionally, we identified assembly and material selection issues with components such as the screen, keyboard, and battery.

To address these issues, Allion utilized micro-strain sensors adhered to the surfaces of the product’s mechanisms to observe micro-level changes. This included monitoring changes in resistance and quantifying them to represent the changes in the mechanism. Simultaneously, we monitored surface changes in materials such as housing and PCBs and quantified the data, enabling comparison of differences before and after testing.

In addition to mechanical issues, Allion also assists in classifying and identifying problems in electrical signal measurements. Through software detection of signal transmission packets, we help customers quickly clarify whether the issue is related to power or data transmission signal problems.

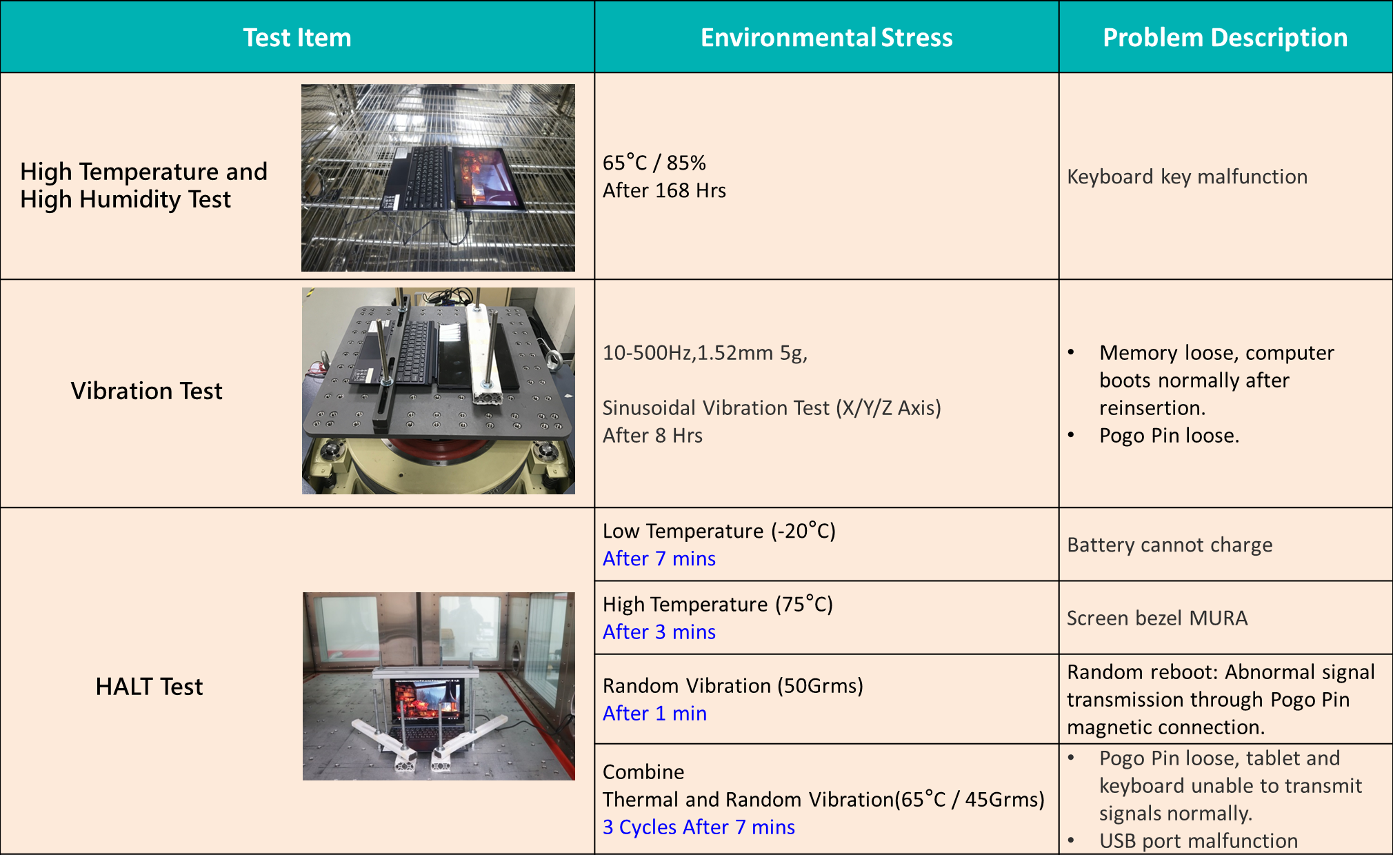

After conducting reliability testing under environmental stress conditions and HALT testing, Allion discovered the following issues with the 2-in-1 laptop:

In this case, we found that in real-world usage scenarios, users experienced the same issues after a period of use. This not only severely impacted user experience but also significantly reduced future purchase intentions. Therefore, after Allion identified the problem and provided adjustment recommendations, the manufacturer decided to proactively improve the design strength of the Pogo Pin and the component selection process on the circuit board. This action also helped to mitigate the risk of potential future repairs and replacements.

Faster, Easier, Better!System Validation Consulting Solutions

As high-frequency and high-speed product applications continue to evolve, relying on traditional reliability testing is no longer enough. That’s where Allion Labs comes in. We understand the critical role that user scenarios play in revealing potential risks. With our vast expertise in user scenario testing, Allion Labs can bring clients with a faster, easier and better technical consulting service, seamlessly integrating user scenario into reliability testing.

We can also tailor our services to meet different product requirements, providing complete signal, functional testing, and relevant certification services. Taking the laptop platform as an example, Allion can verify whether the signals including eDP, PCIe, SATA, HDMI, USB, Thunderbolt, Ethernet, etc., in the customer’s product comply with standards in terms of compatibility and stability. This helps customers identify relevant issues early, rectify errors, and reduce future costs associated with repairs and returns.

Faster

Allion has the capability for combined testing (comprehensive evaluation of high and low temperature, as well as vibration). This includes specification recommendations, supplier selection, and confirmation of sample specifications. Regardless of the product stage, Allion can provide corresponding services for various standards or specifications, assisting customers in accelerating the product testing cycle further.

Easier

Once potential risks in the product are identified, Allion can assist our clients in clarifying the possible causes of the issues and provide debugging support and advice on solutions. This will enhance the quality and overall performance of the product in a simpler manner.

Better

With over 30 years of professional experience, a dedicated technical team, and comprehensive testing environments and equipment, Allion is committed to providing customers with top-notch service quality. Leveraging our extensive experience in user scenario testing, we strive to offer customers even more comprehensive service quality.

If you have any needs for system testing, verification, or consulting services, please feel free to browse the following services or contact us through the online form.

.User Reliability Test Laboratory

.HALT (Highly Accelerated Life Testing Laboratory)