Allion USA-SGS | Casper Lee

In the previous article, we mentioned that due to the rise of NVM (Non-Volatile Memory) and the need for reduced size and increased speed, the form factor of storage devices have evolved from 2.5″ to M.2, and its transmission interface has also changed from SATA to PCIe. M.2 with NVMe storage devices (M.2 SSD) have become the mainstream in the industry on both consumer platforms or servers. From the perspective of testing, the M.2 test fixture has an indispensable role.

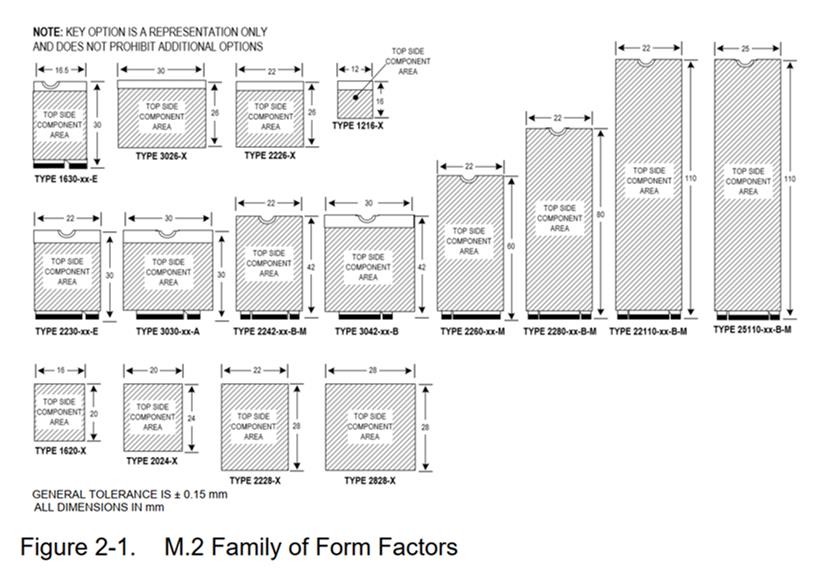

Reference from PCI Express M.2 Specification Rev: 4.0 Version 1.0

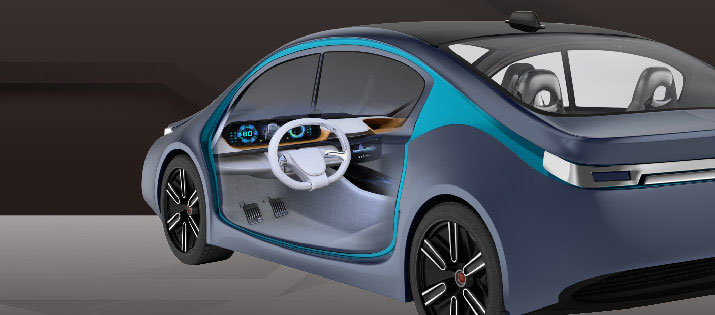

From the diagram above, we can see that the definition of M.2 Form Factor is fairly complicated, with the A, E, A+E, B, B+M, and M Key specifications. Here we will focus on the PCIe M Key (Socket 3) for storage applications and the host test to discuss the design of the test fixture. M.2 SSD has been widely used in a variety of systems, completely replacing HDD in system storage and surpassing the physical limits of traditional storage. Although the current specifications of PCIe Gen 3 can satisfy a large number of applications for general users, developers are now pursuing speed in this generation of cloud services and AI computing, evident in PCIe Gen 4 or even Gen 5. The continual increase in speed opens the opportunity for more PCIe applications, but a large number of tests and validations are required as the products evolve. The issues concerning relevant equipment, instruments, and fixtures required for validation pose even more challenges for developers.

In terms of fixtures, the current M.2 test fixture provided by the PCI-SIG can only test PCIe Gen 3; for PCIe Gen 4, tests must be done with a previous generation test fixture. There are almost no fixtures on the market that can be used for M.2 PCIe Gen 4 testing, and the few that can come with a number of risks.

The PCI-SIG’s M.2 Gen 3 fixture—4 pairs of PCIe TX/RX signals , a reference clock on the 2280 form factor, covered with a total of 18pcs SMP connector cables. The setup is extremely complicated and errors can occur frequently.

In addition, other fixtures on the market use a flexible PCB with a vertically-positioned M.2 device. Though this design can avoid system mechanical issues and solve measurement problems, the stress caused by the vertical positioning will shorten the fixture’s service life. When an expensive fixture cannot withstand long-term use, it creates more trouble than convenience.

Based on Allion’s domain knowhow and decades of testing experience, we understand how complex product testing is, particularly when involving different fixtures, instruments, equipment, and operations. Oftentimes the original fixture is functional, yet its design does not consider how a test engineer actually uses it during testing. This causes unnecessary frustration for the test engineer, so Allion fixed the deficiencies of the original fixture and developed a new M.2 fixture to make it more convenient and stable.

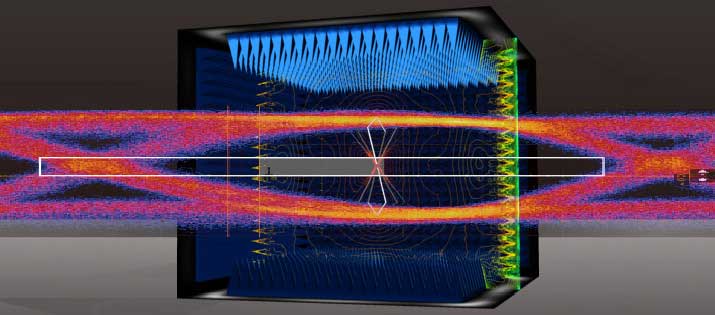

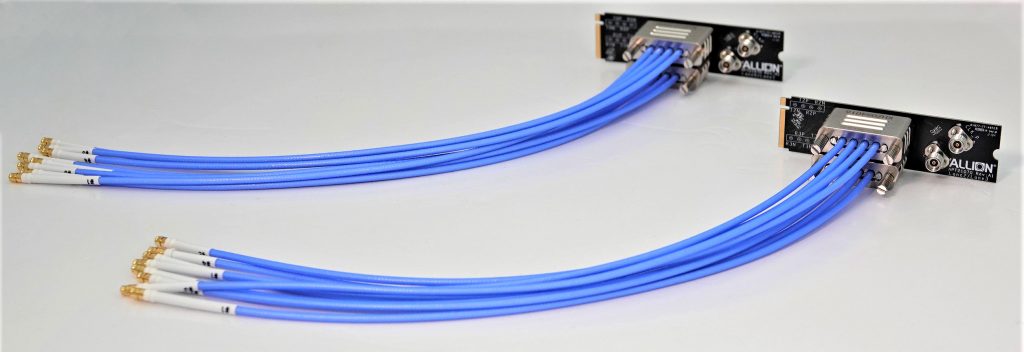

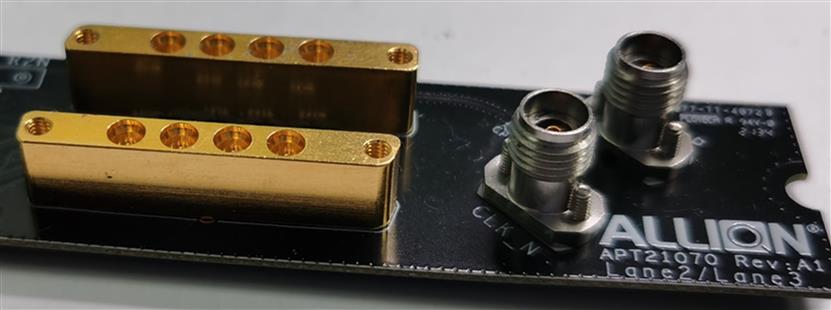

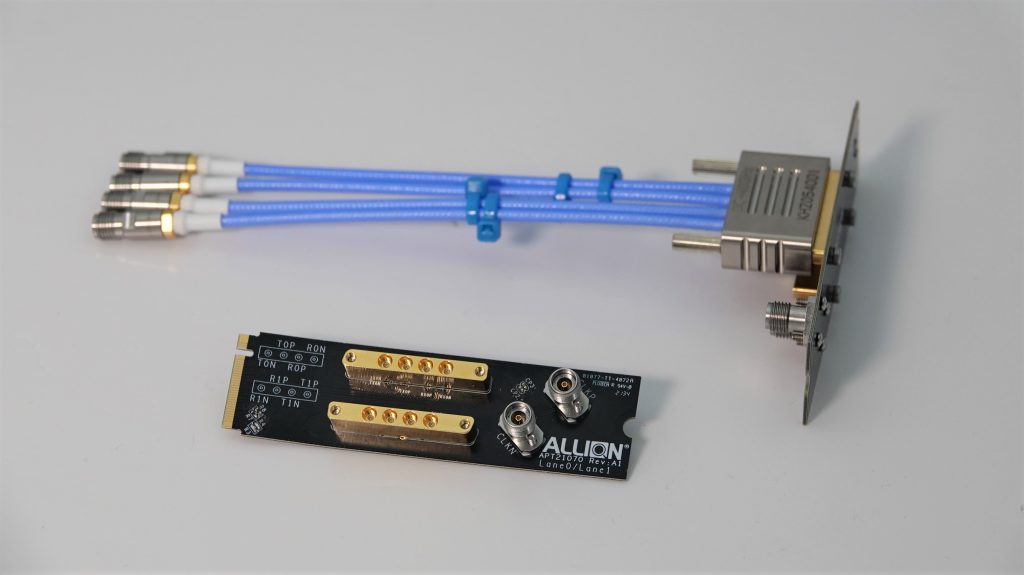

Our fixture has two parts, disassembling the 4 lanes of M.2 PCIe into two groups of Lane0/Lane1 and Lane2/Lane3. At the same time, the cable is integrated into the fixture.

In addition, we have also strengthened the structure of the connector to improve the original connector’s poor tolerance and the doubt that it is easy to cause damage in use. We also adopt specific high-frequency connector with a bandwidth of more than 40 GHz on the fixture.

Allion uses modularization to integrate the test cables, which can be directly connected to related test equipment without additional cables, which can greatly reduce the plugging and unplugging of multiple cables during testing. At the same time, it also has different lengths and connector types to meet the different demands of testing.

You can use a 30 cm SMP cable module to directly connect to the ISI Board of the Association for measuring PCIe Gen 4 and Gen 5 that will be introduced.

You can also use a 15 cm length of K connector cable module to directly connect to oscilloscope with the attenuation value input to measure PCIe Gen 4 or Gen 5 signals. Using fixtures developed by Allion gives you more flexibility and convenience.

Allion adheres to the spirit of providing professional services and solving the difficulties of customers, so our client’s products undergo proper validation in the shortest time possible.

If you have product validation or customized measurement needs, please refer to the Allion Fixture Shopping Center or contact us at: service@allion.com